Lab 3: Timers, Pulse Width Modulation (PWM)

Helpful chapters from the ATmega324P Datasheet

-

- Pin Configurations – section 1.1, page 15

-

- 8-bit Timer/Counter0 with PWM – section 16.9, page 140

-

- 16-bit Timer/Counter1 with PWM – section 17.14, page 173

-

- 8-bit Timer/Counter2 with PWM and asynchronous operation – section 19.11, page 202

1. Pulse Width Modulation

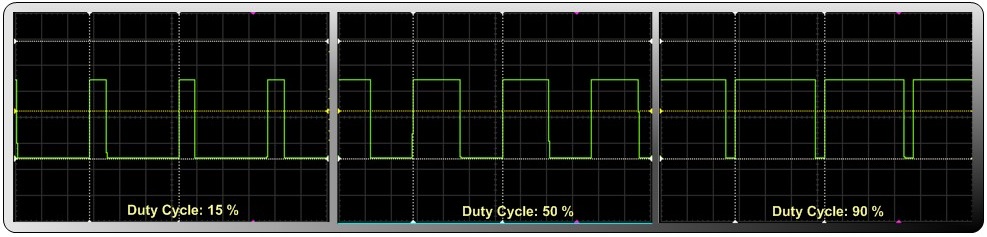

PWM (Pulse Width Modulation) is a technique used to control the voltage applied to an electronic device by quickly switching it between ON and OFF states.

This rapid switching results in an average voltage determined by the time the signal stays ON versus the total cycle time — this ratio is called the duty cycle.

PWM allows digital control over analog signals — for instance:

- Dimming an LED

- Changing the color of RGB LEDs

- Setting the pitch of a buzzer

- Adjusting the speed of a motor

1.1. Operating Principle

The duty cycle is expressed as a percentage of the ON time relative to the total cycle:

The average voltage received by a device is:

PWM signals are typically generated by digital circuits and microcontrollers. The ATmega324 uses a counter that resets periodically and compares its value with a reference (OCRn). When the counter exceeds the reference value, the PWM output toggles its state.

🛠️ PWM via software?

PWM can also be implemented in software using methods like:

- Bit-banging

- Timers with ISR

But for high-frequency PWM (e.g., kHz range for motors), hardware PWM is far more efficient, avoiding CPU overhead from frequent interrupts.

2. PWM on AVR Microcontrollers

In the previous lab, we saw that the ATmega324 has three timers:

Timer0(8-bit)Timer1(16-bit)Timer2(8-bit)

Each timer can be configured via the control registers TCCRnA and TCCRnB, using the WGMnx bits to select the mode:

- Normal

- CTC (Clear Timer on Compare Match)

- Fast PWM (used today!)

- Phase Correct PWM, etc.

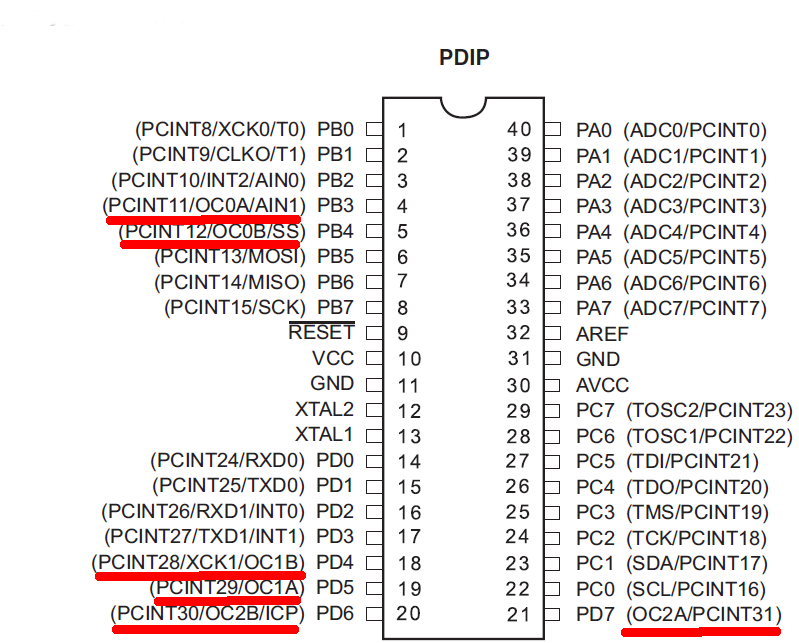

Each timer has two output compare channels: OCnA and OCnB. These are tied to specific physical pins. Check the Pin Configurations chapter of the datasheet for exact mappings:

Today we’ll focus on Fast PWM, a common mode suitable for general applications like LED dimming and motor speed control.

Fast PWM

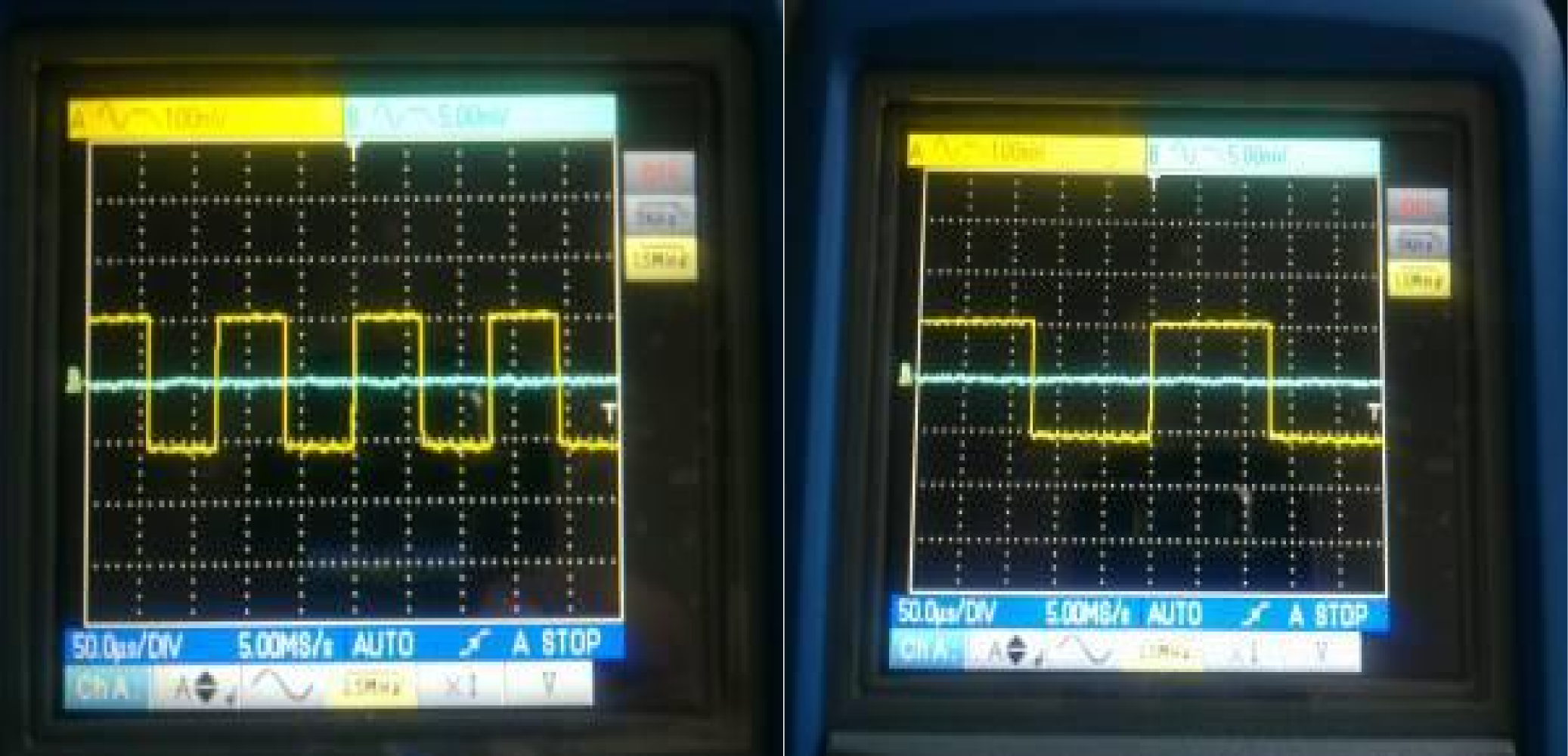

In Fast PWM mode, the timer counts only on the rising edge of the clock signal. The duty cycle changes take effect immediately, but the waveform is not centered — a shift or glitch may appear when changing the duty cycle significantly.

Several Fast PWM modes are available for different timers. For Timer1, you have:

- Fast PWM, 8-bit: TOP = 0x00FF

- Fast PWM, 9-bit: TOP = 0x01FF

- Fast PWM, 10-bit: TOP = 0x03FF

- Fast PWM with TOP in

ICR - Fast PWM with TOP in

OCRnA

In this lab, we’ll use only Fast PWM 8-bit mode. Refer to the datasheet for other timer-specific modes and features.

Suppose Timer1 is configured in Fast PWM mode. This mode has a fixed frequency and allows the duty cycle (threshold) to be modified during execution.

- With mode

10forCOM1A1:COM1A0, the signal on pinOC1Astays HIGH during counting up to the threshold, and LOW afterwards until the end of the cycle. - To get a duty cycle of

x%, set:

OCR1A = x * TOP / 100

whereTOPis 255 (8-bit), 511 (9-bit), or 1023 (10-bit), depending on configuration.

Example: Timer1 in Fast PWM 8-bit, non-inverting mode with 1024 prescaler

PWM frequency ≈ 12 MHz / 1024 / 255 ≈ 45 Hz

/* OC1A is PD5, must be configured as OUTPUT */

DDRB |= (1 << PD5);

/* Select Fast PWM 8-bit mode: WGM[3:0] = 0b0101 */

/* WGM10 and WGM11 -> TCCR1A; WGM12 and WGM13 -> TCCR1B */

TCCR1A = (1 << WGM10);

TCCR1B = (1 << WGM12);

/* Set non-inverting mode on OC1A: COM1A[1:0] = 0b10 */

TCCR1A |= (1 << COM1A1);

/* Set prescaler to 1024: CS1[2:0] = 0b101 */

TCCR1B |= (1 << CS12) | (1 << CS10);

/* Set 50% duty cycle (TOP = 255, so OCR1A = 127) */

OCR1A = 127;

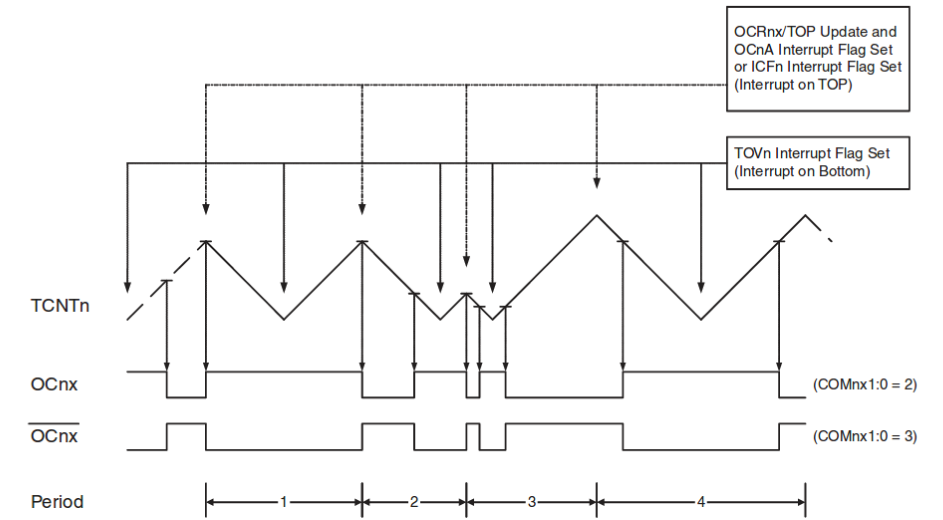

Phase Correct PWM

Although we won’t use this in the lab, it’s useful to understand how Phase Correct PWM differs from Fast PWM — it offers better accuracy, often required for BLDC motors or audio.

Key difference: the counter counts up from BOTTOM to TOP, then back down to BOTTOM.

- Output is set based on comparison with

OCRnx, just like Fast PWM. - However,

OCRnxremains constant during the full cycle, resulting in stable ON durations and cleaner signals. - This avoids frequency shifts (jitter) — important for motors, which can lose efficiency due to inconsistent PWM.

Comparison: Fast PWM vs Phase Correct PWM

3. Exercises

- Lab Work

- Homework

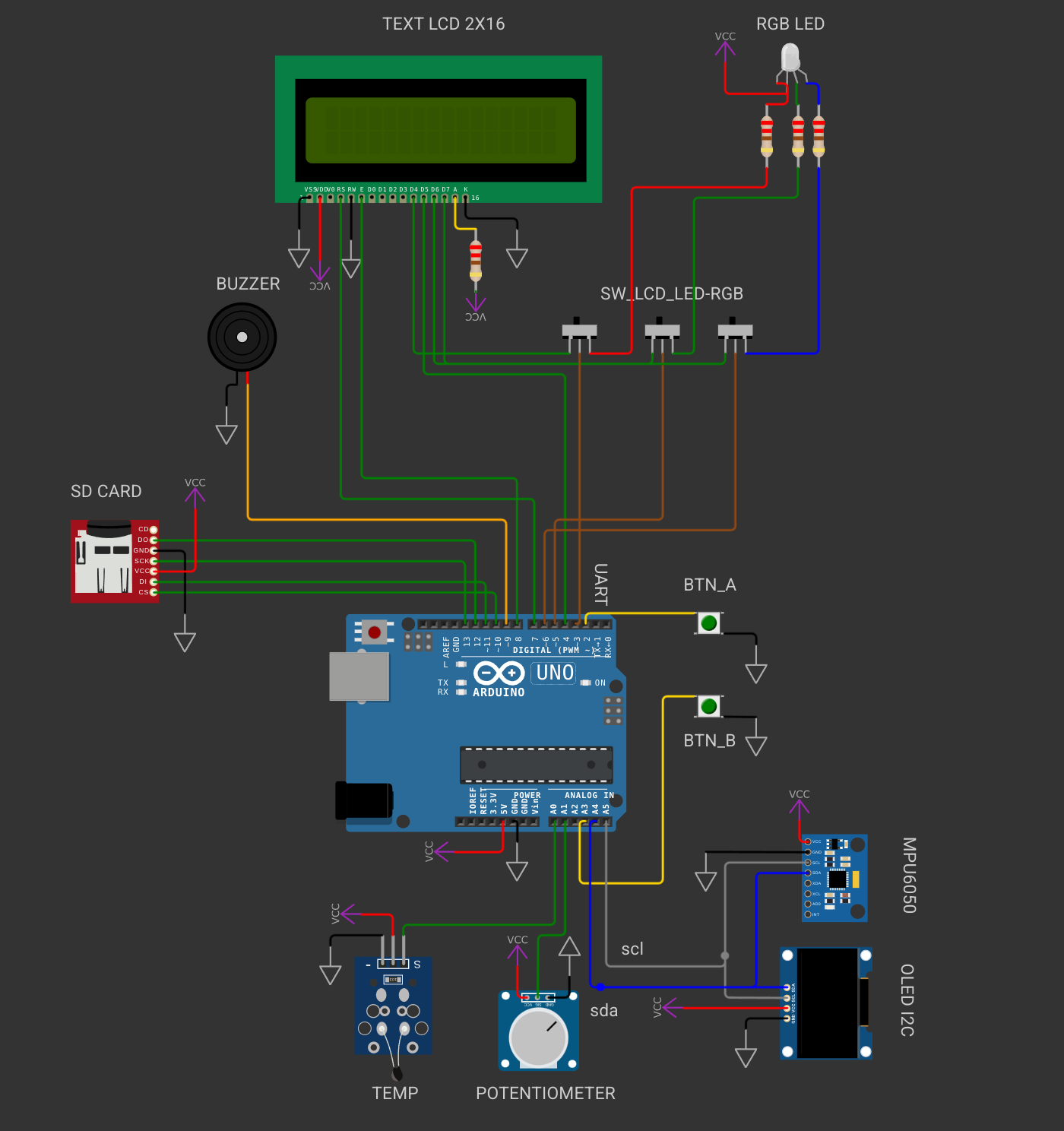

The goal of these exercises is to control the color of an RGB LED using PWM. You can produce any color by adjusting the brightness of each diode (Red, Green, Blue) independently!

The RGB LED pins are connected as follows:

- Red: pin

PD5, functionOC1A(linked to Timer1) - Green: pin

PD7, functionOC2A(linked to Timer2) - Blue: pin

PB3, functionOC0A(linked to Timer0)

The RGB LED is wired with common anode / "active-low" configuration — the LED turns ON when the pin is set to LOW, and OFF when set to HIGH.

Task 0

- Download and run the starter project ZIP.

- What do you observe on the board?

- Check the serial monitor — do you remember how timing was handled in the previous lab?

- How does the LED behave? Which timer is used and in what mode?

- Where is the intensity updated? What input does the formula use, and where is the output applied?

Task 1

- Let’s make the blue LED behave similarly.

- Use Timer0 (

OC0AonPB3) in Fast PWM mode. - Be sure to check Section 12.9 in the ATmega324P Datasheet for proper register usage — Timer0's registers differ from Timer1's!

- Make the blue LED pulse faster than red, and in parallel.

- What do you notice?

- Use Timer0 (

Task 2

- Time to turn on the green LED!

- Challenge:

PD7(OC2A) is used by Timer2, which is already used formillis()system ticks... - Solution: We’ll generate PWM manually using interrupts:

- Timer2 counts from 0 to 188 and triggers an interrupt via

COMPA(to incrementsysticks). - Timer2’s second comparator

COMPBtriggers an interrupt at a value between 0–188. - In

COMPA ISR: turn ON green LED → set GPIO LOW. - In

COMPB ISR: turn OFF green LED → set GPIO HIGH. - Duty cycle is given by

OCR2B.

- Timer2 counts from 0 to 188 and triggers an interrupt via

- Challenge:

Keep OCR2A = 188 to retain proper millis() timing.

Task 3

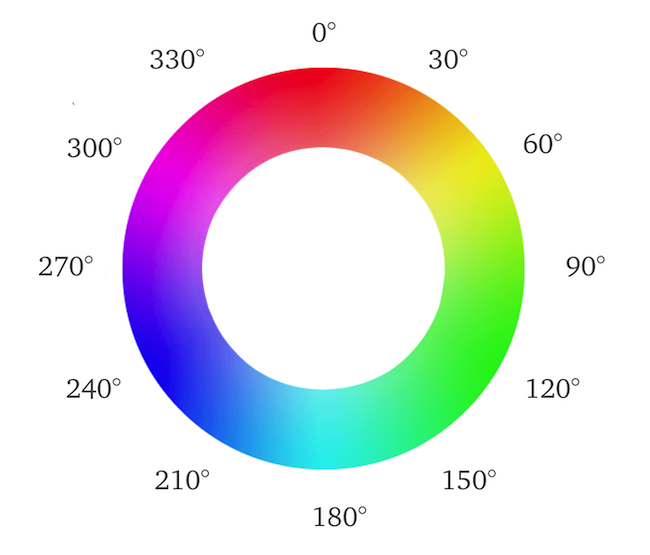

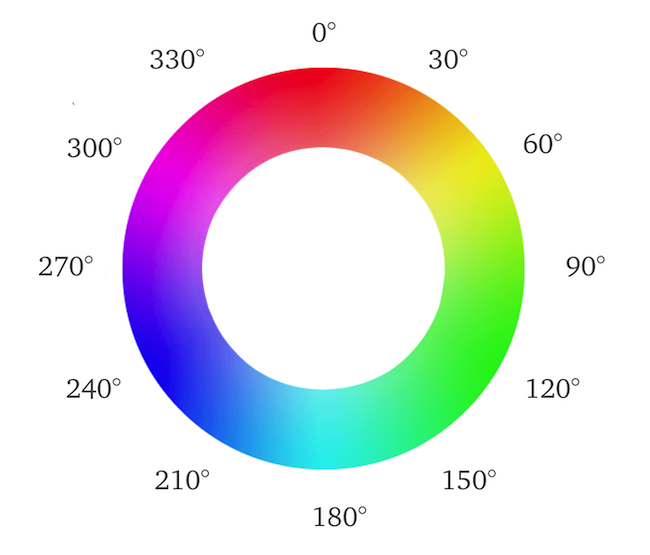

- Cycle through all colors using HSV color space:

- Convert HSV → RGB using provided

convert_HSV_to_RGB()function. - Let

Hueanimate over time, keepSaturation = 1,Value = 1(for full brightness). - Use system ticks to animate the color smoothly, just like LED pulsing.

- Make sure to disable any conflicting code that modifies LED intensity.

- Convert HSV → RGB using provided

Task 4 (Bonus)

- Use the speaker connected to

PD4(alsoOC1B) to play a melody from thesound.cmodule.surprise_notes[]contains frequencies.durations[]stores note durations.- In

update_notes(), reconfigure Timer1 each time a new note is played.- Use CTC mode (

OCR1Asets the TOP → controls frequency). - Set

OCR1B = OCR1A / 2for 50% duty cycle (square wave). - Call

update_notes()every 25ms usingsysticks. - Reset

TCNT1 = 0after changingOCR1Ato avoid timing delays.

- Use CTC mode (

Bonus 2

Combine:

- RGB animation (HSV cycling) and

- Sound playback (melody via speaker)

— both running simultaneously and smoothly.

From now on you will be working with Wokwi because its easier to import libraries. The 📥homework skeleton will be the same for all the labs. You don't need to modify the circuit for the homework. You will only change the .c and .h files. The connections to the peripherals wil be different from the ones in the lab development board. For the homework you will work with Arduino Uno (ATmega328P).

Make sure to read the README.md before solving the exercises.

The goal of these exercises is to control the color of an RGB LED using PWM. You can produce any color by adjusting the brightness of each diode (Red, Green, Blue) independently!

The RGB LED pins are connected as follows:

- Red: pin

PD6, functionOC0A(linked to Timer1) - Green: pin

PD5, functionOC0B(linked to Timer0) - Blue: pin

PB3, functionOC2B(linked to Timer2)

The RGB LED is wired with common anode / "active-low" configuration — the LED turns ON when the pin is set to LOW, and OFF when set to HIGH.

Task 0

- Clone the homework skeleton and readme before starting the exercises. (When running the simulation, make sure to use the switches to use the RGB LED and not the LCD)

Task 1

- Let’s make the RED LED behave similarly.

- Use Timer0 (

OC0Aon PD6) in Fast PWM mode. - Be sure to check Section 12.9 in the ATmega324P Datasheet for proper register usage — Timer0's registers differ from Timer1's!

- Make the blue LED pulse faster than red, and in parallel.

- What do you notice?

- Use Timer0 (

Task 2

- Time to turn on the BLUE LED!

- Challenge:

PD3(OC2B) is used by Timer2, which is already used formillis()system ticks... - Solution: We’ll generate PWM manually using interrupts:

- Timer2 counts from 0 to 188 and triggers an interrupt via

COMPA(to incrementsysticks). - Timer2’s second comparator

COMPBtriggers an interrupt at a value between 0–188. - In

COMPA ISR: turn ON blue LED → set GPIO LOW. - In

COMPB ISR: turn OFF blue LED → set GPIO HIGH. - Duty cycle is given by

OCR2B.

- Timer2 counts from 0 to 188 and triggers an interrupt via

- Challenge:

Keep OCR2A = 188 to retain proper millis() timing.

Task 3

- Cycle through all colors using HSV color space:

- Convert HSV → RGB using provided

convert_HSV_to_RGB()function. - Let

Hueanimate over time, keepSaturation = 1,Value = 1(for full brightness). - Use system ticks to animate the color smoothly, just like LED pulsing.

- Make sure to disable any conflicting code that modifies LED intensity.

- Convert HSV → RGB using provided

Task 4 (Bonus)

- Use the speaker connected to

PB1(alsoOC1A) to play a melody from thesound.cmodule.surprise_notes[]contains frequencies.durations[]stores note durations.- In

update_notes(), reconfigure Timer1 each time a new note is played.- Use CTC mode (

OCR1Asets the TOP → controls frequency). - Set

OCR1B = OCR1A / 2for 50% duty cycle (square wave). - Call

update_notes()every 25ms usingsysticks. - Reset

TCNT1 = 0after changingOCR1Ato avoid timing delays.

- Use CTC mode (

Bonus 2

Combine:

- RGB animation (HSV cycling) and

- Sound playback (melody via speaker)

— both running simultaneously and smoothly.